Open Bar Cast Iron Inlaid Copper Round Gate

Category:

Gate Valve Series

Keywords:

Gate Valve Series

Product Details

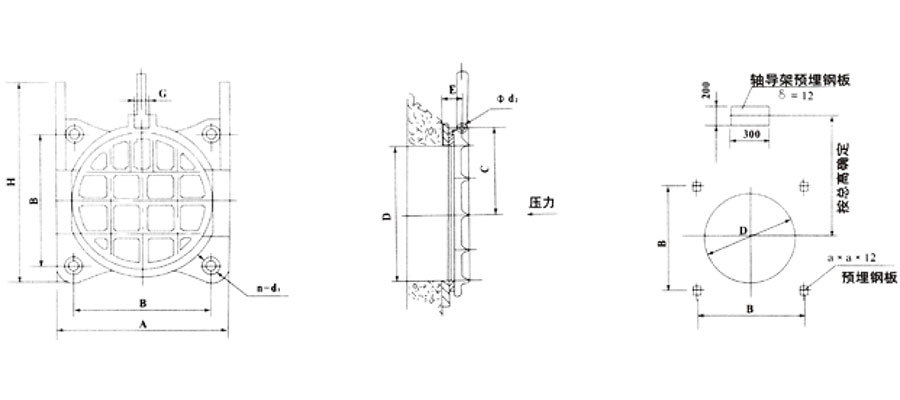

The equipment is mainly composed of door frame, gate plate, sealing ring and adjustable wedge pressing block. After the gate is worn for a long time, its sealing surface can be adjusted by wedge pressing block to ensure normal operation.

It has reasonable structure, strong wear resistance and corrosion resistance, and reliable performance. It is easy to install, debug, use and maintain. Commonly used in water supply, drainage, flood control and other water conservancy projects.

Technical Parameters

The gate should be installed according to the position shown, and the gate plate should be set on the water facing;

The maximum allowable pressure of gate plate pressing to door frame is 0.1MPa;

The maximum allowable pressure of gate plate from door frame is 0.02MPa;

The leakage of the sealing working part is not more than 1.25L/min.m.

Features

DN200-DN1200

| Diameter | Installation size (mm) | Basic size (mm) | |||||||

| D | A | B | C | E | G | H | фd1 | a×a | n×d1 |

| 200 | 382 | 200 | 146 | 70 | 30 | 360 | 18 | 50 | 4×M12 |

| 250 | 426 | 250 | 175 | 75 | 35 | 450 | 18 | 50 | 4 ×M12 |

| 300 | 470 | 300 | 200 | 80 | 40 | 610 | 20 | 50 | 4×M12 |

| 400 | 580 | 400 | 275 | 83 | 40 | 730 | 20 | 100 | 4×M12 |

| 450 | 642 | 450 | 300 | 83 | 45 | 810 | 25 | 100 | 4×M16 |

| 500 | 680 | 500 | 340 | 83 | 45 | 860 | 25 | 100 | 4×M16 |

| 600 | 780 | 600 | 390 | 95 | 56 | 1010 | 32 | 100 | 4×M16 |

| 700 | 890 | 700 | 440 | 110 | 60 | 1180 | 32 | 100 | 4×M16 |

| 800 | 1000 | 800 | 500 | 110 | 65 | 1380 | 32 | 100 | 4×M16 |

| 900 | 1090 | 900 | 550 | 115 | 70 | 1550 | 32 | 100 | 4×M20 |

| 1000 | 1180 | 1000 | 600 | 115 | 80 | 1660 | 36 | 100 | 4×M22 |

| 1200 | 1400 | 1200 | 700 | 130 | 100 | 2020 | 40 | 100 | 4×M24 |

DN1400-DN3000

| Caliber | Installation dimensions (mm) | Basic size (mm) | |||||

| D | A | E | C | H | фd | G | a |

| 1400 | 1630 | 180 | 800 | 2400 | 40 | 110 | 150 |

| 1500 | 1750 | 204 | 850 | 2600 | 40 | 110 | 150 |

| 1600 | 1880 | 204 | 900 | 2600 | 44 | 120 | 200 |

| 1700 | 1950 | 204 | 950 | 2800 | 44 | 120 | 200 |

| 1800 | 2050 | 204 | 1000 | 3200 | 44 | 130 | 200 |

| 1900 | 2170 | 204 | 1050 | 3300 | 50 | 130 | 200 |

| 2000 | 2270 | 210 | 1100 | 3500 | 50 | 140 | 200 |

| 2200 | 2490 | 250 | 1200 | 3960 | 55 | 140 | 200 |

| 2400 | 2690 | 250 | 1300 | 4320 | 55 | 140 | 200 |

| 2800 | 3090 | 280 | 1500 | 5040 | 55 | 150 | 200 |

| 3000 | 3300 | 310 | 1600 | 5400 | 60 | 150 | 200 |

FACTORY

It currently has more than 70 types of equipment such as machining centers, CNC lathes, wire cutting, thread rolling machines, gear rolling machines, centerless grinders, high-frequency quenching machines, etc. The company has successively won the honorary titles of AAA-level credit enterprise, quality service integrity unit, integrity management demonstration unit, and contract-abiding and trustworthy enterprise.

Qualifications

Our company has complete quality inspection equipment and professional quality inspection personnel, and has established a constant temperature physical and chemical laboratory to provide guarantees for customers' strict quality requirements. Our company has passed the IS09001 international quality system certification, the product process quality is controllable, and 100% inspection before leaving the factory provides guarantees for customers' strict quality requirements. In order to meet the growing sales needs, the company continues to improve the level of refined management and is fully equipped with ERP and MES production office software.

FAQ

RELATED PRODUCTS