Electric Three Eccentric Butterfly Valve

Category:

Butterfly Valve Series

Keywords:

Butterfly Valve Series

Product Details

The series of three eccentric butterfly valve adopts three dimensional eccentric metal sealing structure, the sealing form is metal to metal sealing, can be exchanged metal sealing ring to metal sealing, stainless steel plate and composite graphite sealing ring to metal sealing. Therefore, under high temperature and high pressure conditions, it still has stable sealing performance. The special sealing system of this valve guarantees high sealing performance in all temperature ranges from ultra-low temperature to ultra-high temperature.

Technical Parameters

| Nominal diameter (mm) | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | 1000 | 1200 | 1400 | 1500 | ||

| Stream quantity Tie number kv | 1.6 MPa | 60. Opening | 125 | 230 | 365 | 630 | 1100 | 1760 | 2450 | 3250 | 4270 | 5350 | 7000 | 10100 | 13650 | 17800 | 22400 | 28700 | 42600 | 55800 | 63500 |

| 90. Opening | 260 | 470 | 760 | 1300 | 2250 | 3600 | 5000 | 6700 | 8700 | 11000 | 14400 | 21000 | 28100 | 36500 | 45900 | 58800 | 87300 | 144200 | 130200 | ||

| 4.0 MPa | 60. Opening | 110 | 210 | 325 | 550 | 1000 | 1630 | 2220 | 2960 | 3870 | 4900 | 6300 | 9240 | 12400 | 16200 | 20300 | 26000 | 37800 | 50800 | 57800 | |

| 90. Opening | 185 | 330 | 530 | 910 | 1690 | 2700 | 3750 | 5360 | 7000 | 8800 | 11500 | 16800 | 25400 | 33200 | 41600 | 53300 | 77500 | 104100 | 118500 | ||

| Rated stroke | Adjustable type: 60°; Two-position type: 90° | ||||||||||||||||||||

| Flow characteristics | Approximate equal percentage | ||||||||||||||||||||

| Nominal pressure | Standard products 1.6, 4.0Mpa | ||||||||||||||||||||

| Adjustable range | 25:1(60°); 50:1(90°) | ||||||||||||||||||||

| Electric actuators available | Equipped with Q-type, QH-type, YB-type and other series of electronic electric actuators | ||||||||||||||||||||

| Action form | Electric: electric open, electric close | ||||||||||||||||||||

| Flange standard | Clip-type connection complies with JB78-59, JB79-59 standards, and can be produced according to JB-T79.1-94, JB/T9.2-94, HG20592-2009, ANSL, JIS, DIN and other standards | ||||||||||||||||||||

Features

| Valve body material | Cast steel (ZG230-450), stainless steel (ZG1Cr18Ni9Ti, 316, 316L), etc. | |||

| Valve plate material | Stainless steel (ZG1Cr18Ni9Ti, 316, 316L), etc. | |||

| Packing material | PTFE, flexible graphite | |||

| Sealing material | Soft seal | Elastic hard seal | Hard seal | |

| Valve seat material | PTFE | Carbon fiber reinforced PTFE | Stainless steel or stainless steel + STL | Stainless steel or stainless steel + STL |

| Leakage rate | VI level, zero leakage | V level, VI level | V level, VI level | |

| Operating temperature | -40~180℃ | -40~220℃ | -40~450℃ | -40~600℃ |

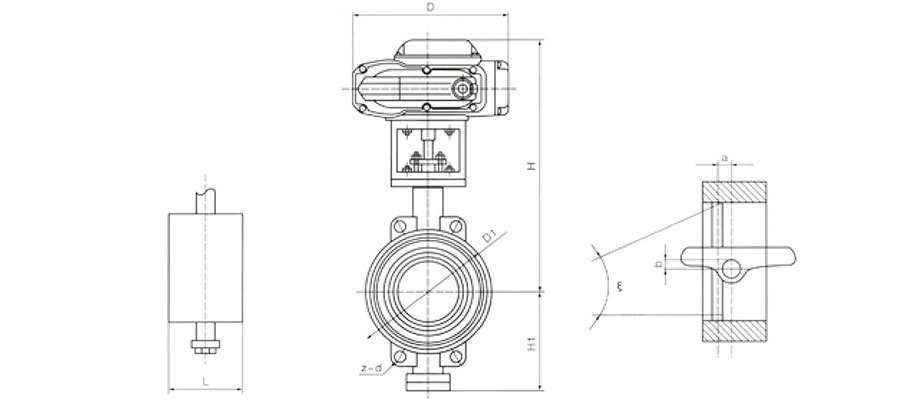

Dimensions

| Nominal diameter (mm) | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | 1000 | 1200 | 1400 | 1500 | ||

| L(mm) | Clamp type | 64 | 64 | 70 | 76 | 89 | 114 | 114 | 127 | 140 | 152 | 152 | 178 | 229 | 241 | 241 | 300 | 360 | 390 | 420 | |

| Flange | 114 | 127 | 140 | 140 | 152 | 165 | 178 | 190 | 216 | 222 | 229 | 267 | 292 | 318 | 330 | 410 | 470 | 530 | 560 | ||

| H1(mm) | 120 | 140 | 170 | 180 | 210 | 240 | 290 | 320 | 350 | 385 | 410 | 450 | 510 | 560 | 630 | 680 | 7910 | 900 | 960 | ||

| With YB type | H (mm) | Normal pad | 375 | 400 | 427 | 440 | 470 | 538 | 588 | 705 | 785 | 855 | 910 | 1010 | 1215 | 1275 | 1325 | 1450 | 1510 | 1640 | 1760 |

| Heat sink pad | 475 | 500 | 527 | 540 | 570 | 638 | 688 | 805 | 885 | 955 | 1030 | 1130 | 1240 | 1300 | 1475 | 1500 | 1660 | 1790 | 1910 | ||

| D(mm) | 203 | 222 | 294 | 300 | 450 | 603 | 683 | 700 | 795 | ||||||||||||

| With Q type | H (mm) | Normal pad | 344 | 369 | 396 | 409 | 439 | 481 | 531 | 561 | 641 | 705 | 760 | 860 | 990 | 1060 | 1120 | 1170 | 1255 | 1380 | 1430 |

| Heat sink pad | 444 | 469 | 496 | 509 | 539 | 581 | 631 | 661 | 741 | 805 | 880 | 980 | 1100 | 1180 | 1250 | 1320 | 1405 | 1530 | 1580 | ||

| D(mm) | 207 | 256 | 380 | 560 | |||||||||||||||||

FACTORY

It currently has more than 70 types of equipment such as machining centers, CNC lathes, wire cutting, thread rolling machines, gear rolling machines, centerless grinders, high-frequency quenching machines, etc. The company has successively won the honorary titles of AAA-level credit enterprise, quality service integrity unit, integrity management demonstration unit, and contract-abiding and trustworthy enterprise.

Qualifications

Our company has complete quality inspection equipment and professional quality inspection personnel, and has established a constant temperature physical and chemical laboratory to provide guarantees for customers' strict quality requirements. Our company has passed the IS09001 international quality system certification, the product process quality is controllable, and 100% inspection before leaving the factory provides guarantees for customers' strict quality requirements. In order to meet the growing sales needs, the company continues to improve the level of refined management and is fully equipped with ERP and MES production office software.

FAQ

RELATED PRODUCTS