Electric Diaphragm Valve

Category:

Diaphragm Valve Series

Keywords:

Diaphragm Valve Series

Product Details

The electric regulating diaphragm valve is composed of Z series, LF series direct travel electric actuator and diaphragm valve. The electric actuator is an electronic integrated structure, with servo amplifier, input control signal (4-20mADC or 1-5DC) and power supply to control the valve opening to achieve the adjustment of pressure, flow, liquid level temperature and other working parameters. performance are obviously improved.

The diaphragm valve body has smooth flow, the throttling element is an elastic diaphragm valve, and there is no packing box on the valve cover. Therefore, the flow capacity is larger than the general control valve and has no leakage, and can be used as a cut-off valve within the range of allowable pressure difference. The valve is suitable for the adjustment of high viscos fluid, suspended particles, fiber media, toxic media and corrosive media. Diaphragm valve is a special form of valve with truncation function, and its opening and closing parts are composed of a diaphragm made of steel valve disc and soft material (rubber and fluorine plastic composite), and the valve body cavity and the valve cover cavity are separated to achieve the purpose of truncating the medium in the tube.

| Valve body material | Applicable temperature | Applicable medium | Nominal pressure |

| Gray cast iron | -50~+150℃ | Corrosive fluid | 0.6、1.0Mpa |

Technical Parameters

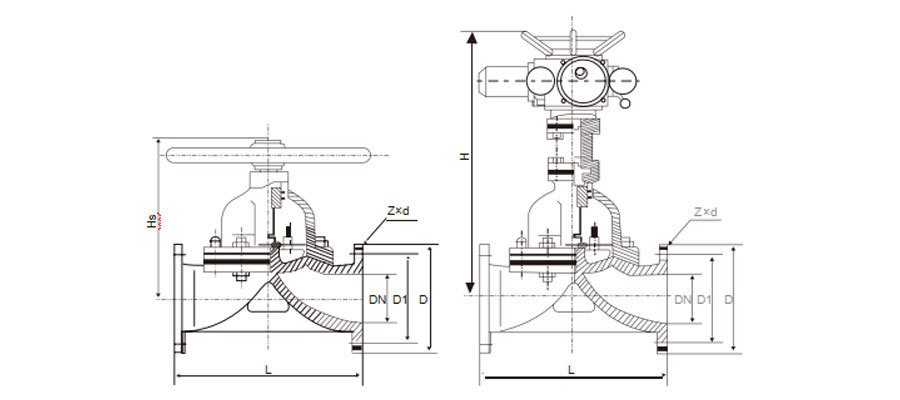

| Main dimensions of valve (mm) | Main parameters of electric device | Motor power (KW) | ||||||||

| DN | L | D | D1 | Zxd | HS | H | Model | Torque (N.m) | Speed (r/min) | |

| 25 | 145 | 115 | 85 | 4xФ14 | 121 | 445 | Z5 | 50 | 12 | 0.12 |

| 32 | 160 | 135 | 100 | 4xФ18 | 132 | 457 | Z5 | 50 | 12 | 0.12 |

| 40 | 180 | 145 | 110 | 4xФ18 | 156 | 466 | Z5 | 50 | 12 | 0.12 |

| 50 | 210 | 160 | 125 | 4xФ18 | 169 | 480 | Z5 | 50 | 12 | 0.12 |

| 65 | 250 | 180 | 145 | 4xФ18 | 202 | 517 | Z10 | 100 | 24/36 | 0.25/0.37 |

| 80 | 300 | 195 | 160 | 4xФ18 | 216 | 539 | Z10 | 100 | 24/36 | 0.25/0.37 |

| 100 | 350 | 215 | 180 | 4xФ18 | 270 | 576 | Z10 | 100 | 24/36 | 0.25/0.37 |

| 125 | 400 | 245 | 210 | 4xФ18 | 338 | 634 | Z15 | 150 | 24/36 | 0.37/0.55 |

| 150 | 460 | 280 | 240 | 8xФ23 | 384 | 660 | Z15 | 150 | 24/36 | 0.37/0.55 |

| 200 | 570 | 335 | 295 | 8xФ23 | 518 | 860 | Z15 | 150 | 24/36 | 0.37/0.55 |

| 250 | 680 | 390 | 350 | 8xФ23 | 598 | 960 | Z20 | 200 | 18/24 | 0.37/0.55 |

| 300 | 790 | 440 | 400 | 8xФ23 | 698 | 1003 | Z20 | 300 | 18/24 | 0.55/0.75 |

FACTORY

It currently has more than 70 types of equipment such as machining centers, CNC lathes, wire cutting, thread rolling machines, gear rolling machines, centerless grinders, high-frequency quenching machines, etc. The company has successively won the honorary titles of AAA-level credit enterprise, quality service integrity unit, integrity management demonstration unit, and contract-abiding and trustworthy enterprise.

Qualifications

Our company has complete quality inspection equipment and professional quality inspection personnel, and has established a constant temperature physical and chemical laboratory to provide guarantees for customers' strict quality requirements. Our company has passed the IS09001 international quality system certification, the product process quality is controllable, and 100% inspection before leaving the factory provides guarantees for customers' strict quality requirements. In order to meet the growing sales needs, the company continues to improve the level of refined management and is fully equipped with ERP and MES production office software.

FAQ

RELATED PRODUCTS